Frequently asked questions

The TK11 Chromium-6 Detection Test Kit

This test kit can be used to detect the presence of chromium-6 on various surfaces, such as paint layers and metals.

Old paint coatings may contain chromium-6 to protect the metal from corroding. The test kit is therefore often used to test if old layers of paint can be safely sanded or ground. Heated metals, often in combination with anti-seize agents, frequently contain chromium-6 on the surface. The test kit is therefore often used for testing heated components in gas turbines, wind turbines, engines, etc.

The test kit is provided with clear instructions and safety data sheets. The test kit can therefore be used by any adult person, and the test is easy to carry out. Of course, the safety precautions should be observed (wearing goggles and gloves) as described in the manual.

This can be done in a simple way:

-In case of a paint layer, the surface should be lightly sanded beforehand.

-Rub the moistened test swab over the surface.

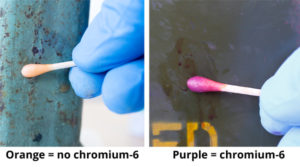

-If the test swab turns purple, it indicates the presence of chromium-6.

-If the test swab remains orange, it indicates that no chromium-6 is present.

Yes, Mechanics, metal workers, painters or quality employees can use our test kit easily, fast and on the spot, by rubbing a moistened test swab over the metal surface. A red/purple discolouration of the test swab indicates the presence of chromium-6, whereas the test swab remaining orange indicates that no chromium-6 is present.

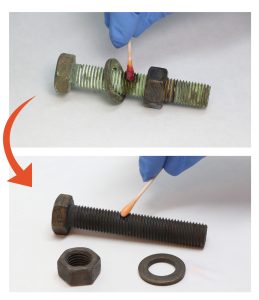

Example of a stainless steel 304 (A2) bolt and nut with anti-seize paste after heat treatment. The formed yellow/green chromate is clearly visible. The test swab of the TK11™ Chromium-6 Detection Test Kit clearly turns red/purple, indicating that chromium-6 is present.

Example of a zinc chromate coating on a hinge of a fence.

1. Testing of the surface of pre-heated machine parts

The machine parts need to be cooled down before you can perform the test. Make sure the parts are below 50˚C.

2. Moisten the test swab properly

Moisten the end of the test swab thoroughly with about 6 drops of test liquid to saturate the test swab completely before testing. Proper moistening leads to the best results as it ensures there is enough liquid in which chromium-6 can dissolve. The bottle of the test kit contains enough liquid for 25 tests.

3. Observing the results

Make sure there is sufficient light, for the observation of the discoloration of the test swab. For example, outside with daylight, or inside with bright artificial light. Usually the presence of chromium-6 results in a distinct purple discoloration. However, a slight red/purple discoloration of the test swab already indicates that chromium-6 is present in a lower concentration.

In case of chromium-6 presence, the swab will turn red/purple promptly. Any color changes after a maximum of 5 minutes should be disregarded.

4. Storage of the test kit

The test kit must be stored in a dry, dark and cool place. The bag containing the test swabs must be sealed well after every use.

5. Removal of chromium-6 using the TK20 Chromium-6 Neutralizer

When chromium-6 is present on the pre-heated machine parts, this can be removed/neutralized by our neutralization fluid. This fluid can be sprayed on the surface of the machine parts and removed afterwards. It is also possible to immerse small parts, such as nuts and bolts, into this liquid.

Yes, we provide a detailed specification for our TK11 Chromium-6 Detection Test Kit. You can download it here.